Fujikura’s speciality splicers are engineered with features to offer customers superior splicing technology and reliability available in the global market. The need for Accurate, Reliable, and Consistent splicing has expanded to applications beyond telecommunications. The speciality splicer series from Fujikura is developed to provide the ultimate in performance and flexibility for diverse markets around the world.

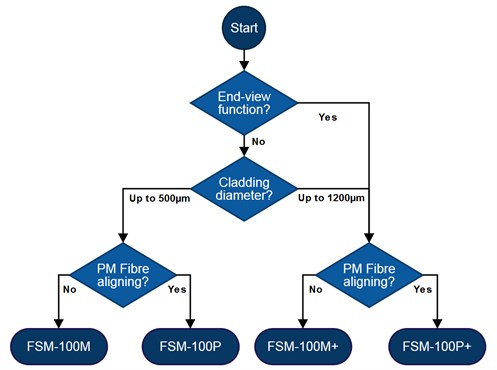

Fujikura FSM-100 series

Splicers

FSM-100M

Key Features:

- Splice 80-500um Clad Fibre

- Up to 13mm cleave length

- +/- 5mm Sweep Length

- FPS Compatibility

FSM-100P

Key Features:

- Splice 80-500um Clad Fibre

- PMF Splicing Capability

- Up to 13mm cleave length

- +/- 5mm Sweep Length

- FPS Compatibility

FSM-100M+

Key Features:

- Splice 80-1200um Clad Fibre

- Up to 26mm cleave length

- +/- 18mm Sweep Length

- Endview Observation System

- FPS Compatibility

FSM-100P+

Key Features:

- Splice 80-1200um Clad Fibre

- Up to 26mm cleave length

- +/- 18mm Sweep Length

- Endview Observation System

- PMF Splicing Capability

- FPS Compatibility

CT-114 Large diameter manual cleaver for up to 660μm cladding fibres

Key Features:

- Applicable fibres: 80 – 660μm cladding

- Manual backstop & clamp force adjustment

- 125μm cladding cleave angle: Avg. 0.2°

- 400μm cladding cleave angle: Avg. 0.3°

- 660μm cladding cleave angle: Avg. 0.4°

- Blade life of approximately 200,000 cleaves with 250μm cladding fibres

- RFID wireless technology – auto cleave mode select using RFID tag

- Auto blade position change

- Touchscreen LCD monitor

- PC software & manual downloadable via USB

CT-115 Large diameter manual cleaver for up to 1250μm cladding fibres

Key Features:

- Applicable fibres: Cladding 80 – 1250μm

- Automatic backstop & clamp force adjustment

- 125um cladding cleave angle: Avg. 0.2°

- 400um cladding cleave angle: Avg. 0.3°

- 660um cladding cleave angle: Avg. 0.4°

- 1000um cladding cleave angle: Avg. 1.0°

- Blade life approximately 200,000 cleaves with 250μm cladding fibres

- RFID wireless technology – Auto Cleave mode select using RFID tag

- Automatic blade position change

- Touchscreen LCD monitor

- PC software & manual downloadable via USB

CT-116 Large diameter manual cleaver for up to 1250μm cladding fibres – angled cleaving

Key Features:

- Applicable fibres: cladding 80 – 1250μm

- Angled Cleaving: 0 to 15°

- Automatic backstop & clamp force adjustment

- 125μm cladding cleave angle: Avg. 0.2°

- 400μm cladding cleave angle: Avg. 0.3°

- 660μm cladding cleave angle: Avg. 0.4°

- 1000μm cladding cleave angle: Avg. 1.0°

- Blade life approximately 200,000 cleaves with 250μm cladding fibres

- RFID wireless technology – Auto Cleave mode select using RFID tag

- Auto blade position change

- Touchscreen LCD monitor

Fujikura Speciality Cleavers

CT-110 Automatic fibre cleaver

Key Features:

- Applicable fibres: cladding 80 – 250μm

- 125μm cladding cleave angle: Avg. 0.3°

- Coating adjuster clamp: alter fibre coating length

- Automatic tension and blade position adjustment

- RFID technology and PC connection

- Applicable using FH-100, FH-110 and FH-70 fibre holders

- Battery or AC adapter compatibility

CT-111 Automatic optical cleaver (with angled cleaving)

Key Features:

- Applicable fibres: cladding 80–25μm.

- 125μm cladding cleave angle: Avg. 0.3°.

- Angled Cleaving: 0–15°.

- Coating adjuster clamp: alter fibre coating length.

- Automatic tension and blade position adjustment.

- RFID technology and PC connection.

- Applicable using FH-100, FH-110 and FH-70 fibre holders.

- Battery or AC adapter compatibility.

CT52 Durable, simple optical fibre cleaver

Key Features:

- 125um Clad Fibre

- Coating up to 900um

- SMF/MMF up to 12 Fibres

- Cleaving Length 3-20mm

- Fibre Plate or FH-100, FH-70 Holders

- Auto Blade Rotation & Bluetooth

- Blade Height Adjustment Dial

CT58 Optical silica fibre cleaver

Key Features:

- 80um Clad Fibre

- Coating up to 400um

- SMF/MMF Single Fibre

- Cleaving Length 3-20mm

- Fibre Plate or FH-100, FH-70 Holders

- Auto Blade Rotation & Bluetooth

- Blade Height Adjustment Dial

Fujikura Recoaters

FSR-115 Optical fibre recoater without proof test function

Key Features:

- Applicable fibre coating diameter – 90μm to 970μm

- Recoat length: 4mm to 50mm

- RFID mould identification – Auto Recoat Mode selection

- Easy user exchangeable mould

- Fast pumping mechanism for cycle time reduction

- Laser light illumination – ease of viewing during resin injection

- Touchscreen technology

FSR-116 Optical fibre recoater with proof test up to 2kgf

Key Features:

- Applicable fibre coating diameter – 90μm to 970μm

- Recoat length: 4mm to 50mm

- Linear proof tester: Up to 2 kgf

- RFID mould identification – Auto Recoat Mode selection

- Easy user exchangeable mould

- Fast pumping mechanism for cycle time reduction

- Laser light illumination – ease of viewing during resin injection

- Touchscreen technology

FSR-117 Optical fibre recoater with proof test up to 10kgf

Key Features:

- Applicable fibre coating diameter – 90μm to 970μm

- Recoat length: 4mm to 50mm

- Mandrel proof tester up to 10 kgf

- RFID mould identification – Auto Recoat Mode selection

- Easy user exchangeable mould

- Fast pumping mechanism for cycle time reduction

- Laser light illumination – ease of viewing during resin injection

- Touchscreen technology

Fujikura Strippers

HTS-12 High tensile stripper for silica fibres

Key Features:

- Single Count 125um or 80um Cladding Fibre

- 250um UV Cured Coating or Optional Blade

- 35mm Maximum Strip Length

- Heating Time: 3 sec

- FH-100, FH-40 series applicable holders

PCS-100 Polyimide coating stripper

Key Features:

- Conventional Silica Optical Fibre Stripping (Polyimide & Carbon Coated)

- Cladding Diameter: 60 – 1200um

- Coating Diameter: 60 – 1500um

- Stripping Length: 1 – 35mm (Window Stripping 1 – 33mm)

- FH-100 series applicable holder

SS110 Automatic Fibre Stripper

Key Features:

- Applicable fibres (cladding/coating): 125/250μm, 80/160μm, 125/900μm, 250/400μm, 400/550μm & custom blade options.

- User replaceable blades.

- Stripping length up to 35mm.

- RFID technology and PC connection.

- Works with FH-100, FH-110, and FH-70 fibre holders.

USC-03

Key Features:

- High Intensity Vibratory Single Fibre Cleaning Action

- ≥99% IPA or Ethanol

- 49mm Max (Adjustable) Fibre Cleaning Length

- FH-40, 50, 70,100 Series Applicable Holders

- 1-99 Seconds Adjustable Timer.

Fujikura Preparation Machine

APM-101/102

Key Features:

- Automatic Stripping/Cleaning/Cleaving Operation

- 125um Cladding/250um Coating

- Approx. 23 Seconds Operation Times

- 3-10mm Cleave Length

- FH-100 Holders – APM-101

- FH-70 Holders – APM-102

Key Features:

- C02 Laser Heat Source for Splicing & Glass Shaping

- Auto Align Fibre Clad Size 80-2300um (2.7mm Camera Field View)

- 150mm Left & Right Z Travel (150mm Max Taper Length)

- Clamp Fibre Glass or Coating Capability

- FH-100, 40, 45 Fibre Holder Compatibility (Custom Fixtures Available)

- PMF Splicing Capability (Optional)

- Endview Observation System (Optional)

- FPS Compatibility

Compatible Applications for all LZM Models:

- Low Melting Point Fibre Splicing

- Shaped Fibres (E.g. Ball Lens, Axicon Lens)

- End-caps

- Capillaries & Over-Clad

- TCE – Thermal Core Expansion

- MFA – Mode Field Adapters

- PCF – Photonic Crystal Fibres

- Combiners

- Tapers

LZM-125 Series Laser Splicing System

Key Features:

- C02 Laser Heat Source for Splicing & Glass Shaping

- Auto Align Fibre Clad Size 80-2000um (2.3mm Camera Field View)

- Clamp Fibre Glass or Coating Capability

- FH-100, 40, 45 Fibre Holder Compatibility (Custom Fixtures Available)

- FPS Compatibility

Model Versions:

LZM-125M (Without PMF Rotation & Endview)

LZM-125P (With PMF Rotation & Without Endview)

- Left & Right Z Travel 5mm (Sweep Length up to 10mm)

- Maximum Taper Length 8mm

LZM-125M+ (Without PMF Rotation & With Endview)

LZM-125P+ (With PMF Rotation & Endview)

- Left & Right Z Travel 18mm (Sweep Length up to 36mm)

- Maximum Taper Length 32mm

LZM-125A+ (With PMF Rotation, Endview & Cladding Ablation)

- Left & Right Z Travel 18mm (Sweep Length up to 36mm)

- Maximum Taper Length 32mm

- Secondary Beam, Cladding Mode Stripper & Fibre Polishing Capability